|

ALL GROUND DOWN-HOW GETTING THE GRINDING RIGHT MAKES FOR RELIABILITY cont... |

||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||

|

Smallest

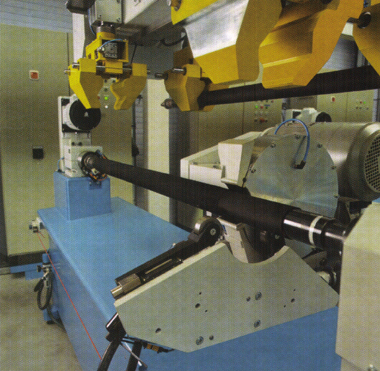

possible tolerances required Keeping the importance of the weight amount of compression in mind and then going back to how the produced hoses look, the question must arise if such a hose can function optimally. Looking at the outer surface of a newly produced hose the print of the wrapping is visible. Height differences of this print are measured to values exceeding 1.0 mm. Secondly there is a tolerance on the inner as well as on the outer diameter of a hose. Adding up the tolerances gives a significant difference between a hose produced in the low tolerances with a smaller new one is as simple as it is effective: grinding the outer surface of the hose to a uniform wall thickness (Figure 8).

Figure 8. The outer surface of Watson-Marlow Bredel's hoses are ground to a uniform wall thickness. |

The

effects of the grinding process on the dimensional tolerances and the over-compression

of the hose are

shown

Figure 9. The print left by the bandaging is clearly visible on this finished non-Watson-Marlow Bredel hose.

Watson-Marlow

Bredel emphasizes the importance of grinding the rubber hoses used for

hose pumps. This way only

one geometrical tolerance is introduced, which can be controlled very

accurately. A regular outer

surface is created as well as a uniform wall thickness ensuring a

constant compression force without peak values.

The constant load on the hose and the pump results in their

longevity, a synergy that symbolizes the quality of the Watson-Marlow

Bredel products. |

|||||||||||||||||||||||||||||||||||||||||||