|

WORLD PUMPS ®

GRINDING RIGHT MAKES FOR RELIABILITY |

||

| Watson-Marlow Bredel Hose

Pumps invests in advanced grinding machinery

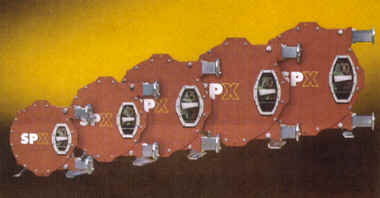

Specialist pump manufacturer Bredel Hose Pumps BV designed the high pressure hose pump in 1973, and since then has successfully completed more than 65,000 installations in industries as diverse as chemical processing, food processing, brewing, paper manufacturing, mining, and waste and water treatment. The company recently invested 2.2 million in custom-built automatic grinding equipment. In this article from the Netherlands, Tiemen Postma, Development Engineer Rubber & Hose Technology, explains the importance of the grinding process for the reliable operation and longevity of Watson-Marlow Bredel’s hose pumps. In a hose pump,

a composite, reinforced hose is enclosed within a casing that is flanged

at both ends. The flanges

are connected to the suction and discharge lines of the system (Figure

1). The principal of operation is as simple as it is reliable.

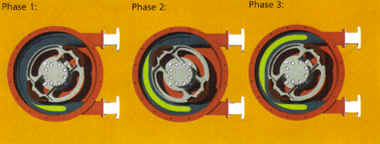

Within the casing is a rotor with two pressing shoes opposite

each other across its center line and mounted on a shaft supported on

its own bearings. As the

rotor rotates the hose is totally compressed by the shoes and the

product within the hose is pushed forward (Figure 2).

Figure 1. The SPX series from Watson Marlow Bredel Hose Pumps |

The

hose: the

heart of the matter So, the hose

(Figure 3) is the heart of the hose pump.

If it does not function correctly the pump will not have optimal

performance. In cooperation

with the company’s hose manufacturing division, Watson-Marlow Bredel

has some 30 years of experience in developing, designing and producing

hoses for the hose pump. Traditionally,

development of new rubber-related products is done by

‘trial-and-error’ methods. This

can often be a time-consuming process.

To shorten development time, and therefore save material and

money, Watson-Marlow Bredel developed a finite element analysis (FEA)

simulation model (Figure 4). The

model can for instance be used to determine the optimal geometry by

looking for the best stress-strain distribution and a minimum of

hysteresis (heat development). Of course, rubber is a material that is hard to model due to its non-linear behavior. Watson-Marlow Bredel realizes that such a FEA model is only a reflection of reality and will have its discrepancies. Therefore practical tests are still necessary to back up the calculations and guarantee a satisfactory service life of the hose.

Figure 2. Principal of operation of a Watson-Marlow Bredel Hose Pump Fully

automated grinding machinery

Numerous hoses are available on the market in various qualities for industrial hose pump applications. One of the first obvious differences between these hoses is the outer surface: ground or non-ground. From the mechanical point of view, |

|